Expansion vessels for potable water and service water applications

Expansion vessels for potable water and service water systems as well as for specific applications in closed water systems meet the requirements of current standards and hygiene requirements. All water-carrying parts are protected against corrosion.

Your benefits:

Full range from 0,65 liter to 5000 liters from own production facilities

Used by many renowned manufacturers in OEM applications

DVGW, WRAS, ACS, Watermark. KWWA approval available

- Only for systems not required to meet DIN 1988, such as fire-fighting and service water systems, underfloor heating

- Components in contact with water are corrosion-protected

- Non-replaceable diaphragm according to DIN EN 1383

- Max. operating temperature 70°C

- Pre-charge pressure: 2.0/4.0 bar

- Approval according to Pressure Equipment Directive 97/23/EC

- Long-lasting epoxy resin coating

- With factory-pressurised gas chamber

- WRAS and ACS certified

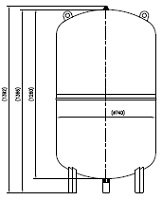

| Type | Dimensions | Height H | Height h | perm.op. overpressure | Connection |

| 25 | Ø 280 | 510 | - | 10.0 | G1" |

| 50 | Ø 409 | 588 | 113 | 10.0 | R1" |

| 80 | Ø 480 | 680 | 104 | 10.0 | R1" |

| 100 | Ø 480 | 785 | 104 | 10.0 | R1" |

| 140 | Ø 480 | 997 | 104 | 10.0 | R1" |

| 200 | Ø 634 | 883 | 91 | 10.0 | R1" |

| 300 | Ø 634 | 1,184 | 93 | 10.0 | R1" |

| 400 | Ø 740 | 1,173 | 81 | 10.0 | R1" |

| 500 | Ø 740 | 1,392 | 82 | 10.0 | R1" |

| 600 | Ø 740 | 1,629 | 73 | 10.0 | R1" |

- Only for systems not required to meet DIN 1988, such as fire-fighting and service water systems, underfloor heating and geothermal installations

- Components in contact with water are corrosion-protected

- Bladder according to DIN EN 13831/replaceable from 50 litres

- Max. operating temperature 70°C

- From O 1,000 mm including pressure gauge

- Approval according to Pressure Equipment Directive 97/23/EC

- Long-lasting epoxy resin coating

- WRAS and ACS certified

| Type | Diemensions | Height H | Height h | perm. op. overpressure | Connection |

| 0.65 | Ø 122 | 130 | - | 10.0 | G 1/2" |

| 1 | Ø 122 | 170 | - | 10.0 | G 1/2" |

| 2 | Ø 132 | 260 | - | 10.0 | G 3/4" |

| 8 | Ø 206 | 335 | - | 10.0 | G 3/4" |

| 12 | Ø 280 | 307 | - | 10.0 | G 3/4" |

| 18 | Ø 280 | 410 | - | 10.0 | G 3/4" |

| 25 | Ø 280 | 520 | - | 10.0 | G 3/4" |

| 33 | Ø 354 | 454 | - | 10.0 | G 3/4" |

| 33 | Ø 354 | 520 | 66 | 10.0 | G 3/4" |

| 50 | Ø 409 | 604 | 102 | 10.0 | G 1" |

| 60 | Ø 409 | 734 | 161 | 10.0 | G 1" |

| 80 | Ø 480 | 745 | 153 | 10.0 | G 1" |

| 100 | Ø 480 | 850 | 153 | 10.0 | G 1" |

| 200 | Ø 634 | 967 | 150 | 10.0 | G 1 1/4" |

| 300 | Ø 634 | 1,267 | 150 | 10.0 | G 1 1/4" |

| 400 | Ø 740 | 1,256 | 139 | 10.0 | G 1 1/4" |

| 500 | Ø 740 | 1,516 | 133 | 10.0 | G 1 1/4" |

| 600 | Ø 740 | 1,859 | 263 | 10.0 | G 1/2" |

| 800 | Ø 740 | 2,325 | 263 | 10.0 | G 1/2" |

| 1000 | Ø 740 | 2,805 | 263 | 10.0 | G 1/2" |

| 1000 | Ø 1,000 | 2,001 | 286 | 10.0 | DN65/PN16 |

| 1500 | Ø 1,200 | 1,991 | 291 | 10.0 | DN65/PN16 |

| 2000 | Ø 1,200 | 2,451 | 291 | 10.0 | DN65/PN16 |

| 3000 | Ø 1,500 | 2,521 | 320 | 10.0 | DN65/PN16 |

| 4000 | Ø 1,500 | 3,070 | 320 | 10.0 | DN65/PN16 |

| 5000 | Ø 1,500 | 3,635 | 320 | 10.0 | DN65/PN16 |

Further standard vessels are also available in 16 bar and 25 bar